can you put wood in a kiln

Heres what you need to know. Though the heat can cause the linoleum to become discolored with time.

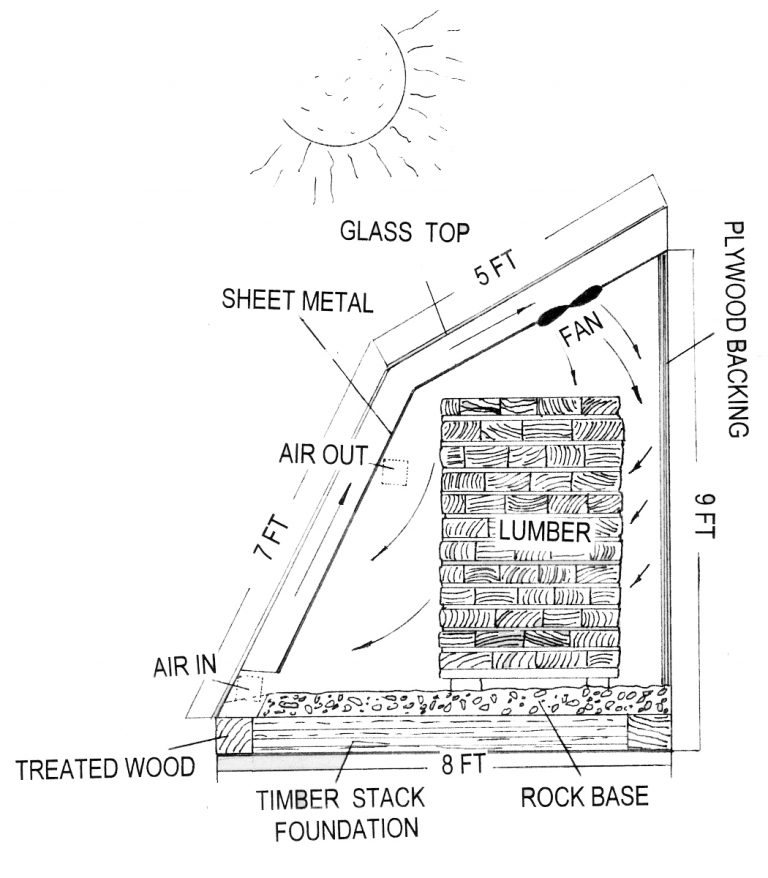

Basics Of Solar Lumber Drying Oklahoma State University

Within 24 hours a kiln can be run and emptied.

. This list is updated regularly. Kiln Firing. Reclaimed wood that has shrunk is much harder to install and can cause a lot of unnecessary headaches during and after the installation process.

However a wooden floor can be acceptable if you use the stand the kiln was supplied with. On the other hand the second technique requires you to stack the treated lumber in a criss-cross layout. You should not put a kiln directly on a wooden floor.

Your stacks of wood should be off of the ground and also be covered at the top to prevent it from getting wet. The first technique involves drying the wood using a dehumidifying kiln. Some potters will use a kiln on a linoleum floor surface.

Or you have a bug. To order call toll-free 1-888-636-4478. I can go on and on about how people misuse these kilns.

Firing fuel-burning kilns can be more of an art than a science. As you near the top of the kiln it is better to not have shelves as close to each other again. Not only the kilns are fast in heating up but also cool down quickly.

Although woodworkers have several different types of kilns to choose from for drying lumber the kiln-drying resources offered above are for kilns that are inexpensive to construct and simple to operate. After a few months bring the wood indoors and finish the drying. Make sure there is good support under the legs of the stand.

Leave enough space to have a standard household dehumidifier at one end and a small fan at the other. I dropped the wood and picked it back up and still the kiln said I did not have processable items. They include using a wood kiln or laying out the wood flat.

For example the time re-quired to kiln dry green 44 red oak to a final mois-ture content of 7 percent is two to three times that. Place the tar paper on the frame. It is not always possible to have shelves placed like this.

Cover the frame with insulation board. And have at least 2 of non-combustible boards underneath the kiln. As mentioned by the other responders your wood burning stove cannot get hot enough to use as an actual kiln.

A layer of cement board strips under those would also be a good idea as they would allow air flow under the boards. Fuel-fired kilns need to be attended during the beginning of their warm-up period until the flashpoint of the fuel the temperature at which the fuel ignites has been reached. We deliver heat logs peat wood pellets and kiln dried wood direct to your door and you can order from us 365 days a year.

This should extend at least 12 from the base of the kiln. An ideal flooring material is concrete. Lumber can be sorted by species moisture con-tent heartwood and sapwood wetwood grain grade thickness and length.

I saw dry and process hard maple for the billiards industry. Species Some species of wood have markedly different drying characteristics than others. If you are interested in learning to use a fuel-fired kiln find a class or a nearby potter who will teach you the ropes.

The cost for the plans and materials list is 995 plus 495 SH. There are two primary strategies to dry pressure treated wood without warping. If you load same species same size all sawn at about the same time you will get excellent results.

This convenient feature prevents the potter from waiting for two days or more. A variety of kiln technologies exist today. It is best to have 8 inches between the top most shelf and the lid when it is closed.

A kiln can only be placed on a wood floor if it is used on its supplied stand and there are at least 2 layers of cement board under it. Since it is a special kind of wood it needs to be treated with a little bit of. So you have a new wood stove or outdoor fire pit youre planning to put to use.

If youre interested in building your own wood drying kiln this post is for you. Alternatively you can position your kiln on concrete paving slabs. As those who have some know kiln dried wood isnt exactly normal wood.

If your kiln is in a garage or basement you may already have a concrete floor. Install the fan optional Thats why many woodworkers build their own wood drying kilns. The kiln will fire slower with a tighter load especially if the load is tight in the bottom of the kiln.

Then youre not carrying the correct thing or youre not using the kiln and are trying to put wood in the smelter. Connect the clear corrugated plastic. You can dry air-dried lumber also - just dont expect the few green pieces you want to include at the last minute to dry.

How to fix hardwood floor cupping. To build the kiln lay poly clear plastic roll on the ground and then build a frame with 2x4 studs on top of it for the lumber to rest on. If you want to build a kiln for pottery in.

As a result it offers flexibility to the users and allows them to test several firing processes like glazes lusters and decals. It seemed to resolve itself after I restarted the game though. You can store kiln dried wood outside as long as it is properly stored.

Can you put wood in a kiln.

Can You Store Kiln Dried Wood Outside Outdoor Barren

Kiln Dry Wood At Home Step By Step Method Garden Tool Expert

How To Kiln Dry Wood Wood Drying Kiln Guide

Logosol Sauno Wood Drying Kiln How To Build And Set Up Youtube

What Is Kiln Dried Lumber And How Is It Used When Building A Home

Everything You Need To Know About Kiln Dried Wood In A Nutshell

My Wood Drying Kiln Wood Kiln Corner Wood Stove Wood Shed

Why Is Air Dried Timber Better Than Kiln Dried For Joinery Quora

What Is Kiln Drying The Reasoning Behind Drying Wood

What Is A Solar Kiln And How Do You Build One

Everything You Need To Know About Kiln Dried Wood In A Nutshell

Kiln Drying Firewood Batch 3 In Drying And Processing

Building A Solar Wood Drying Kiln Solar Kiln Wood Kiln Wood Shed

A Simple Approach To Drying Lumber Woodshop News

Solar Dried Lumber Moisture Concerns Solar Kiln

Air Dry Vs Kiln Dry Woodworking Blog Videos Plans How To